Diecasting is an important procedure in modern manufacturing, widely used to make premium steel components along with precision as well as toughness. In Malaysia, the Diecasting market has actually expanded considerably, steered through innovations in innovation, skilled effort, and also a tough manufacturing sector. The country has come to be a center for Diecasting operations, providing components to a variety of fields like automobile, aerospace, electronic devices, as well as durable goods. With the raising demand for lightweight and high-strength metallic parts, Malaysian Diecasting business have constantly strengthened their capabilities, combining innovative production procedures to satisfy global standards. The important area of Malaysia, coupled along with its own well-developed structure as well as business-friendly plans, has made it a recommended place for Diecasting production. As markets remain to evolve, Malaysia continues to be at the center of precision Diecasting, offering trustworthy options for each regional and also international markets.

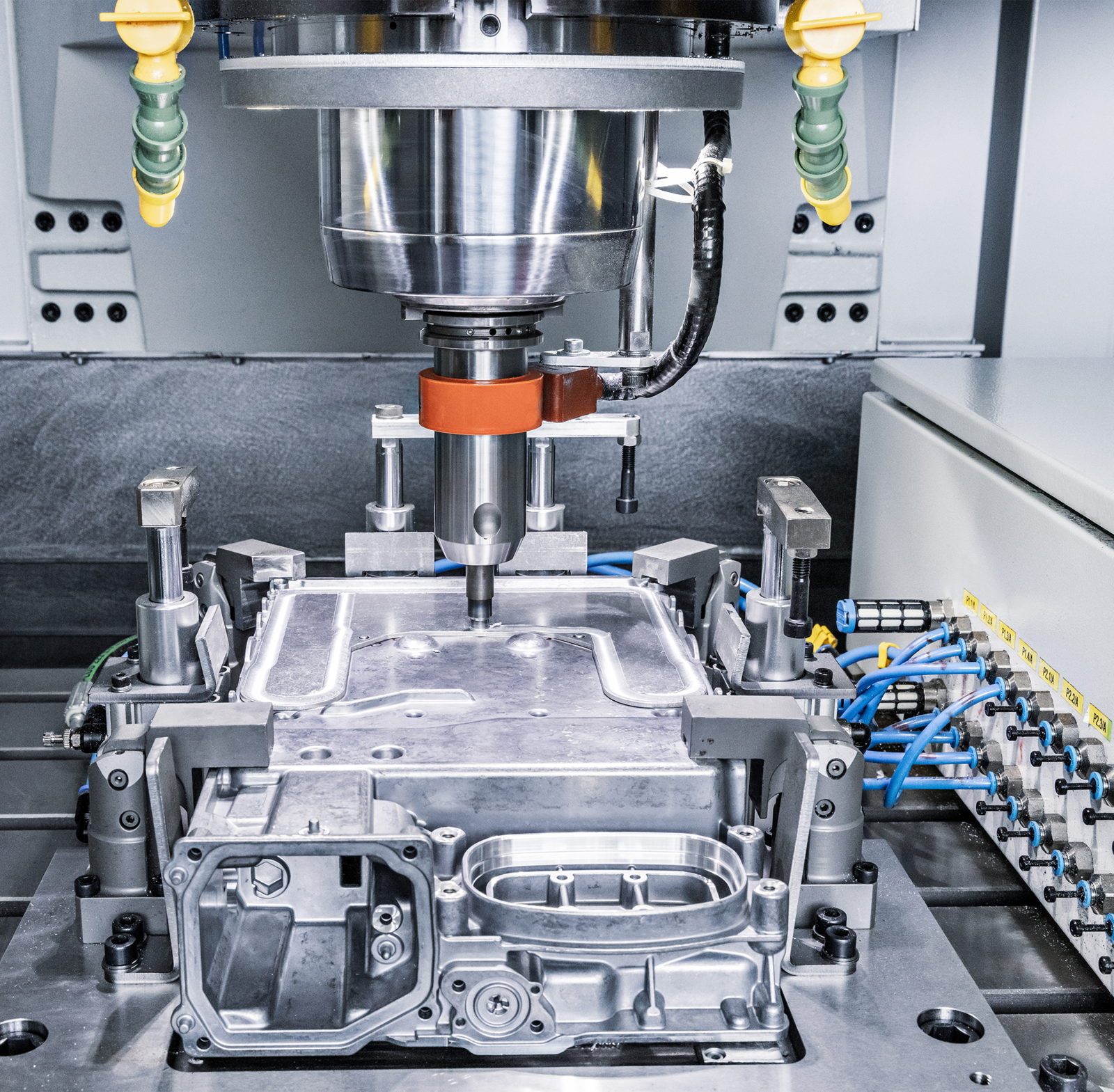

The Diecasting procedure in Malaysia mainly entails two major kinds: high-pressure Diecasting and low-pressure Diecasting. High-pressure Diecasting is the best often used method, where molten metallic is shot right into a mold and mildew cavity under higher stress, allowing the swift production of complex as well as exact parts. This approach is actually widely hired in the motor vehicle and also electronic devices sectors, where higher reliability as well as toughness are required. On the contrary, low-pressure Diecasting is actually used for manufacturing much larger parts with premium technical residential or commercial properties, creating it optimal for sectors such as aerospace and also commercial machines. Many Diecasting providers in Malaysia likewise provide secondary processes including CNC machining, area procedure, and setting up to make sure that finished products meet the particular requirements of their clients. The continual adopting of enhanced Diecasting innovations has actually enriched effectiveness and premium, producing Malaysia a forerunner in this particular industry.

One of the vital perks of the Diecasting business in Malaysia is its own potential to make cost-efficient and also top quality steel elements. The performance of the Diecasting process enables for automation with very little material waste, creating it an ideal choice for makers seeking money-saving answers. Also, die-cast parts possess excellent perspective accuracy, removing the demand for extensive post-processing, which even more lessens manufacturing prices. Malaysian suppliers have likewise purchased automatic Diecasting bodies, strengthening creation rate and also uniformity while sustaining strict quality assurance actions. The ability to create lightweight yet durable elements has resulted in the field’s growth, specifically in fields where weight decline plays a crucial function, such as automobile as well as aerospace. By constantly optimizing creation approaches, Malaysia has positioned itself as a very competitive gamer in the global die appointing market.

The motor vehicle market is one of the biggest consumers of die-cast parts in Malaysia, relying upon these components for engine casings, gear box scenarios, architectural brackets, and other crucial uses. As the vehicle sector shifts in the direction of power autos , the demand for light-weight aluminum die-cast components has increased dramatically. Malaysian Diecasting companies have actually conformed to this style through building concentrated metals and methods to fulfill the strict needs of EV producers. Also, a lot of regional organizations have actually created collaborations with global motor vehicle labels, supplying precision-engineered die-cast components that improve motor vehicle efficiency and fuel productivity. With the growth of environment-friendly technology and lasting manufacturing, Malaysia’s Diecasting field carries on to innovate, sustaining the transition to more green transportation services. For more information please visit here https://www.senadiecasting.com.my/

Past the automotive field, Diecasting spreading in Malaysia additionally participates in an essential job in the electronic devices as well as telecoms fields. Several digital gadgets and elements require die-cast properties and warm drains to guarantee effective warm waste as well as security coming from external factors. Along with the swift growth of individual electronics as well as 5G modern technology, Malaysian suppliers have sized up their die appointing abilities to meet the increasing demand for high-precision components. The potential to generate intricate as well as light-weight elements with exceptional thermal energy has actually produced Malaysian Diecasting business crucial distributors for worldwide modern technology companies. In addition, the government’s campaigns to advertise innovative production and digitalization have further reinforced Malaysia’s place as a favored destination for Diecasting companies in the electronic devices field.

The future of Diecasting in Malaysia appears promising, along with continual investments in study, growth, and automation. As the need for high-performance metallic components develops, Malaysian suppliers are centering on sustainable methods, such as reusing aluminum composites and decreasing energy intake in the production procedure. The combination of Sector 4.0 innovations, featuring expert system and also information analytics, is also helping companies strengthen performance, minimize issues, as well as enrich item high quality. Along with an experienced workforce, sturdy industrial framework, as well as devotion to innovation, Malaysia continues to be a principal in the worldwide Diecasting business. As additional industries find light-weight and also heavy duty metallic options, the Malaysian Diecasting industry is prepared to extend even more, strengthening its own track record as a leader in accuracy manufacturing.

Leave a Reply